Flexible Filler (Putty) 250g

Related products

Polyethylene (EVA) foam is the basic building material for armor or larger proprieties.Enough with the cheap, porous mats! Get our foam and turn into a knight, robot or other...

Polyethylene (EVA) foam is the basic building material for armor or larger proprieties.Enough with the cheap, porous mats! Get our foam and turn into a knight, robot or other...

Polyethylene (EVA) foam is the basic building material for armor or larger proprieties.Enough with the cheap, porous mats! Get our foam and turn into a knight, robot or other...

Foam Clay is the biggest hit of recent years! The whole cosplay scene knows about him, but not everyone has had the chance to touch him. Ideal for decorating larger properties...

Foam Clay is the biggest hit of recent years! The whole cosplay scene knows about him, but not everyone has had the chance to touch him. Do you want to try it yourself? Order a...

- Black

- Red

- Yellow

- Green

- Grey

- Light pink

- Orange

- Tyrkysová modrá

- Broskvová

- Světle fialová

- Purple

- Light blue

- Sytě modrá

- Jasně modrá

- Tmavě modrá

- Tmavě růžová

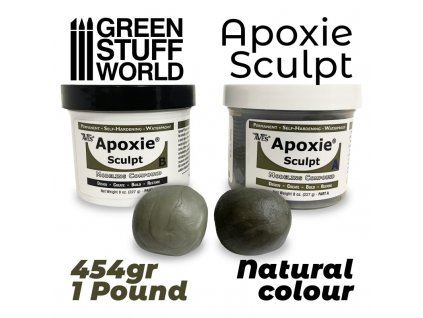

Two-component epoxy modeling compound, similar to Apoxie Sculpt. It hardens in the air, no need to bake. Ideal for producing small details.

Milliput putty is a versatile and popular epoxy putty used by modelers, sculptors, and DIY enthusiasts for various applications. It is a two-part putty made up of two separate...

A simple hard clay with epoxy clay features, but easy to work with just like modeling clay. Very beginner friendly. Great for detailing.

ThermoArt Black Art is an extruded thermoplastic manufactured in Spain by Green Stuff World in sheets, designed specifically for the cosplay world. This material shares the...

![ThermoArt BLACK ART [Foto Web] 03](https://cdn.myshoptet.com/usr/www.cosplayshop.cz/user/shop/detail/1829_thermoart-black-art--foto-web--03.jpg?67f9192e

)

ThermoArt Black Art is an extruded thermoplastic manufactured in Spain by Green Stuff World in sheets, designed specifically for the cosplay world. This material shares the...

Product detailed description

For optimal application, follow these steps:

Surface Preparation:

Ensure that the EVA foam or thermoplastic is clean, dry, and free of dust and grease.

If necessary, lightly sand the surface with a fine-grit sanding pad to create a slightly rough texture and improve adhesion.

Application Process:

Use a small spatula, silicone applicator, or even your fingers to spread a thin layer over the joints or gaps.

Avoid over-applying as excess material will require additional sanding later.

Smoothing the Surface:

While the surface is still wet, dip your finger in water and gently smooth it to reduce the need for sanding later.

For deeper gaps, apply in thin layers, allowing each layer to dry before adding another.

Drying time:

Depending on the thickness of the applied layer and the ambient temperature, drying can take from 15 minutes to an hour.

To speed up the process, place the part in a warm, well-ventilated area.

Sanding for a seamless finish:

After it has completely dried, sand the surface with fine sandpaper (320-600 grit).

Avoid excessive pressure to maintain flexibility.

Painting and finishing:

Once the surface is smooth, apply a primer and acrylic paint for the final finish.

Its properties ensure that the paint adheres without cracking, even if the part is slightly bent.